|

|

Post by britplumber on Dec 23, 2011 22:02:51 GMT 1

Hi All, Thanks to Nathan, I'm now the proud owner of a Cutaway M2AC, I think we were both happy with the deal, me especially. I did some digging around prior to purchase and decided that the missing parts shouldn't be too hard to find (Except for a deact breech block) and could be expensive, but worth it I reckon. I cleaned all the dust off and scotchbrighted some of the rust away so I could fit some 'Borrowed' parts from one of my M2HBs. I've got some photos here of it on a M3 tripod, there a still a few items missing as the donor HB is missing them. When I was doing some research I soon realised that it is a correct US cutaway and not a dealer / DIY job and that they don't appear too common or at least know one is too fussed as there isn't alot of info on them. Anyway, when I've shot blasted it and refinished it, it will look A1.    |

|

|

|

Post by woodsy on Dec 24, 2011 2:16:26 GMT 1

Well done Chris! That is a nice addition to your collection. It would also look very nice next to my cutaway .303 Mk II Browning!  |

|

|

|

Post by britplumber on Dec 24, 2011 13:22:28 GMT 1

Thanks Rod, It will be nice when I've refinished it and found the missing parts. The breech block and Buffer arn't sectioned as I've borrowed them from one of my M2HBs along with the trigger bar, rear cartridge stop, top cover parts, return spring etc. I was tempted to fit the HB barrel and support but decided that because the AC barrel shroud wouldn't budge, I'd leave it be.

|

|

|

|

Post by Kev on Dec 24, 2011 23:25:25 GMT 1

Very nice example Chris should like great !

Lets have some pictures when you have finished it.

ATB Kevin

|

|

|

|

Post by mmike956 on Dec 25, 2011 14:07:23 GMT 1

MAN! What a beauty! That would take alot of work to produce without a milling machine. Maybe I'll light my torch. By the way, The trunnion adapter will have to be removed and the the screw in the top of the threaded stub removed before the barrel jacket can be unscrewed. I've seen very tight ones before but none that couldn't be removed. A little heat will go a long way. Don't use a pipe wrench! I have one here that someone removed with one. A rod through the rear most holes should suffice after a little heat is applied. When you see hot grease oozing out fron the threads you can begin applying torque to the jacket. Since your jacket is intact at the rear you should be ok with a little heat and torque.

|

|

|

|

Post by mmike956 on Dec 25, 2011 14:11:25 GMT 1

What parts do you need to finish it with? Can parts be sent ? Personally I wouldn't refinish it. It would be difficult at best to replace the original finish. What a find! I have a two piece buffer housing that I could weld back together then cut a section away. A buffer piston is easy enough to get one's hands on as are the springs. Let me know how I can help you.

Mike

|

|

|

|

Post by britplumber on Dec 26, 2011 15:51:37 GMT 1

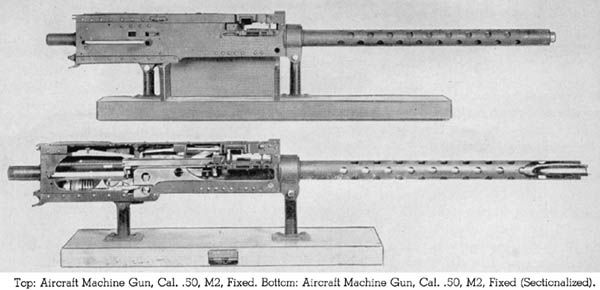

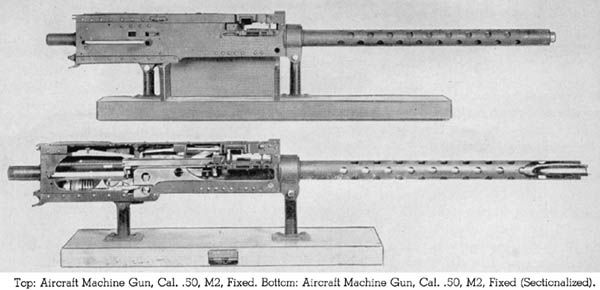

Hi Mike, I'm unsure as yet what parts could be sent from abroad but a friend in the UK maybe able to help out with some parts but I'll maybe take you up on your offer in the future and thankyou for the offer, it is appreciated. The only reason I was thinking of refinishing it is the surface rust on the parts, if anyone can suggest a way to remove stubbon rust with out removing the park then I'm all ears, I tried scotchbright on the rust, it works but it also removes the park too. It was the trunnion adapter I gave up trying to remove, I'm sure it will go but I decided to leave it for now. Has any one any ideas on how to display said piece? I like it on the M3 Tripod but its not correct, or I can make a plynth like the one in the pic  |

|

|

|

Post by woodsy on Dec 26, 2011 20:17:32 GMT 1

Chris, I firmly believe that the original style plinth is the way to go. It not only keeps it in the manner of original issue but also makes it easy to display. Tripods just take up too much room, especially the M3. I keep my .50's on the wall and the tripods stand in the corner until they are needed for a display.

|

|